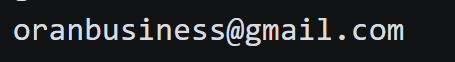

66X Cheaper Injection Molding - My Journey to Affordable Manufacturing

What if I told you that learning the secrets of injection molding doesn’t have to cost $8,000 for just one part? I’m here to share how I achieved it for a fraction of the price—and picked up a ton of knowledge along the way.

2024-08-14

Introduction

What if I told you that learning the secrets of injection molding doesn’t have to cost $8,000 for just one part?

I’m here to share how I achieved it for a fraction of the price—and picked up a ton of knowledge along the way.

Initial Attempts and High Costs

Seven years ago, inspired by innovative projects like Flipper Zero, I wanted to create my own injection-molded parts. However, the quotes I received were disheartening. A single mold and production run in the U.S. came with an $8,000 price tag, and that didn’t even cover the setup or minimum run requirements. My dream seemed unattainable as I stared at a $2,000 minimum quote from Protolabs.

But then I thought, "There must be a cheaper way."

How I Learned: Paying for the Process

My goal was clear: find a way to learn injection molding and save $8,000—equivalent to the cost of a used 2012 VW Beetle.

I quickly realized that what I was really paying for wasn’t the product but the process itself. I didn’t care about the initial product quality; I wanted to understand the steps and answers to all the unknowns.

While Exploring Guadalajara

In my quest, I took a trip to Guadalajara, combining a vacation with a business exploration. Initially, I faced rejection after rejection. But posing as a representative of a stealth-stage startup, I finally secured a visit to a manufacturing facility that reminded me of those seen on Scotty from Strange Parts.

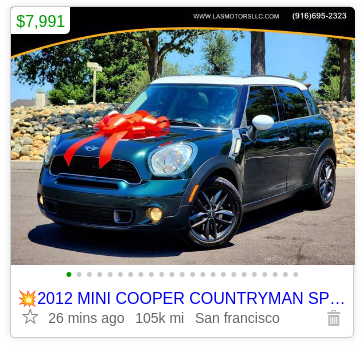

The factory tour was an eye-opener. They quoted $8,000 for the mold with a minimum run of a million parts. However, the head of sales suggested cheaper molds made in China, costing around $2,000 to $4,000 for the mold alone. Once again, I thought, "There must be a cheaper way."

**Hitting the “Manufacturing Motherlode”™

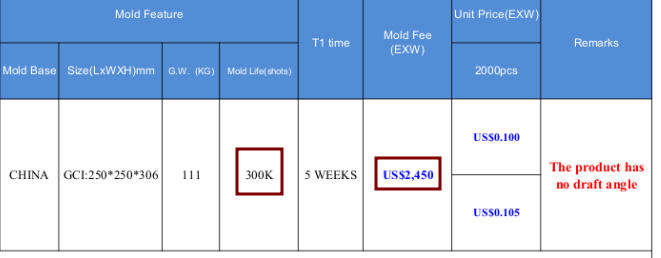

Enter Alibaba. After discovering this online marketplace, I started inquiries into affordable injection molding. The first reality check came when a listing claimed a price of just $5 USD, but I was quoted $2,500 for molds and parts with a minimum order of 2,000 pieces.

The Strategy to Lower Costs

Negotiation became my best tool. I initially asked for a large order to gather detailed quotes. But the breakthrough came when I discovered a niche process: Silicone Replica Injection Molding. This was perfect for smaller runs, allowing me to achieve my goals without the massive upfront cost.

Here’s how it played out:

- Me: “Can I have a quote for 2,000 parts?”

- Factory: “Sure! It’s going to be $2.5k USD.”

- Me: “Wow, that’s a great price! But unfortunately, I can’t afford that. Is there any other option?”

- Factory: “Yes, we do offer Silicone Replica molding.”

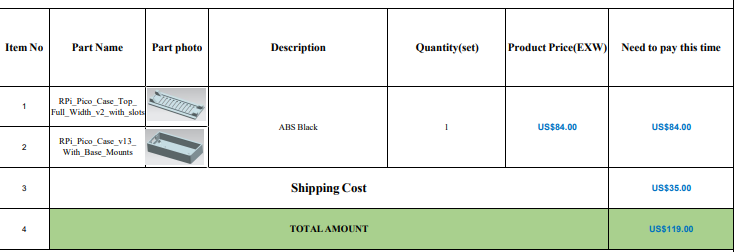

Perfect! This was exactly what I needed. I asked for just one part, knowing it would cost significantly more per piece, and agreed to a quote of $120 USD.

The Drama Unfolds

After placing my order, I received a DHL tracking number but no photos or confirmation. My anxiety grew, especially when the first transaction was lost due to a simple bank number error. But it wasn’t a scam. The part was already shipped, and I sent the payment again, trusting the process.

What is Silicone Replica Injection Molding?

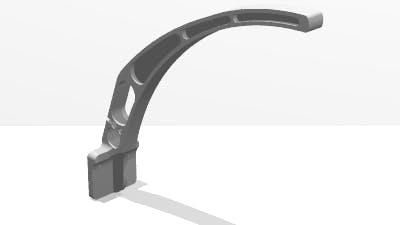

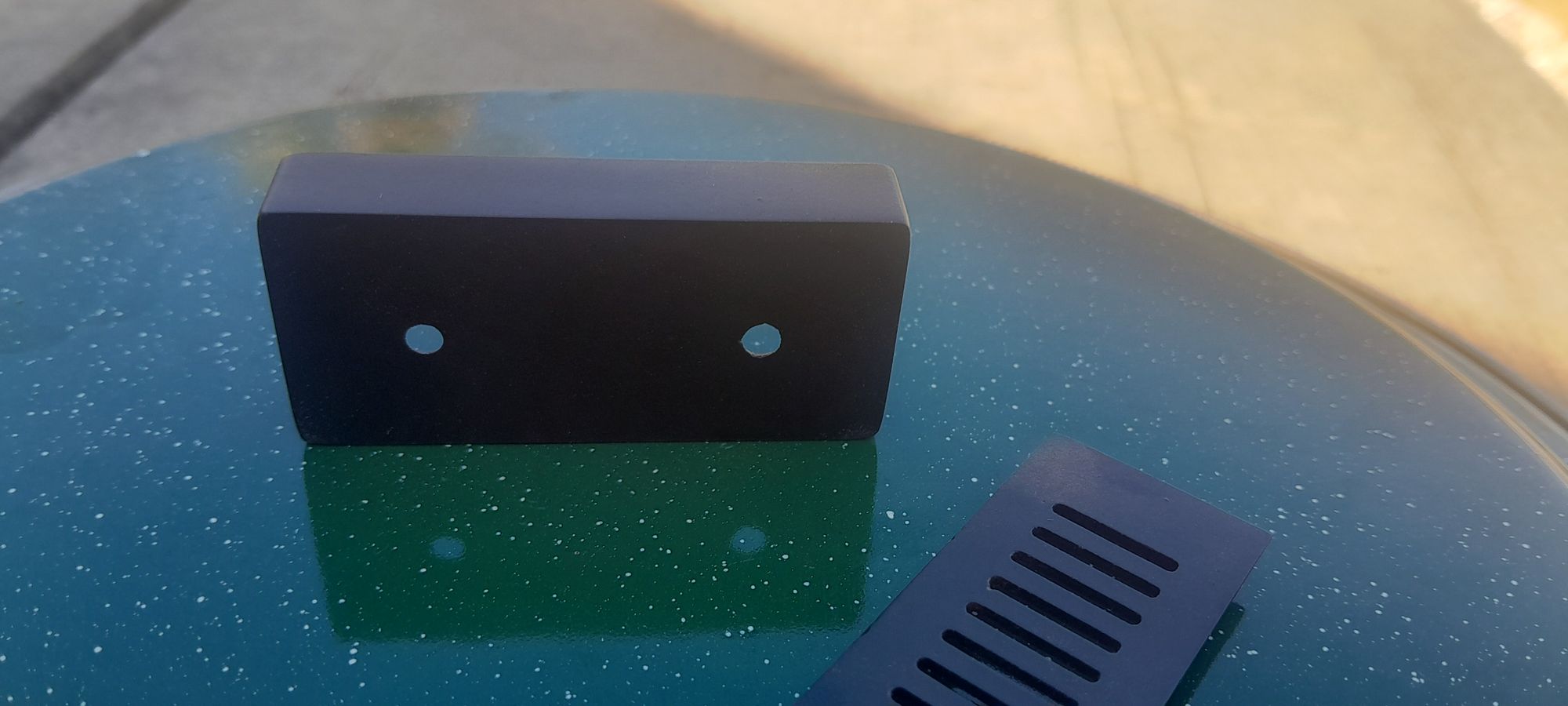

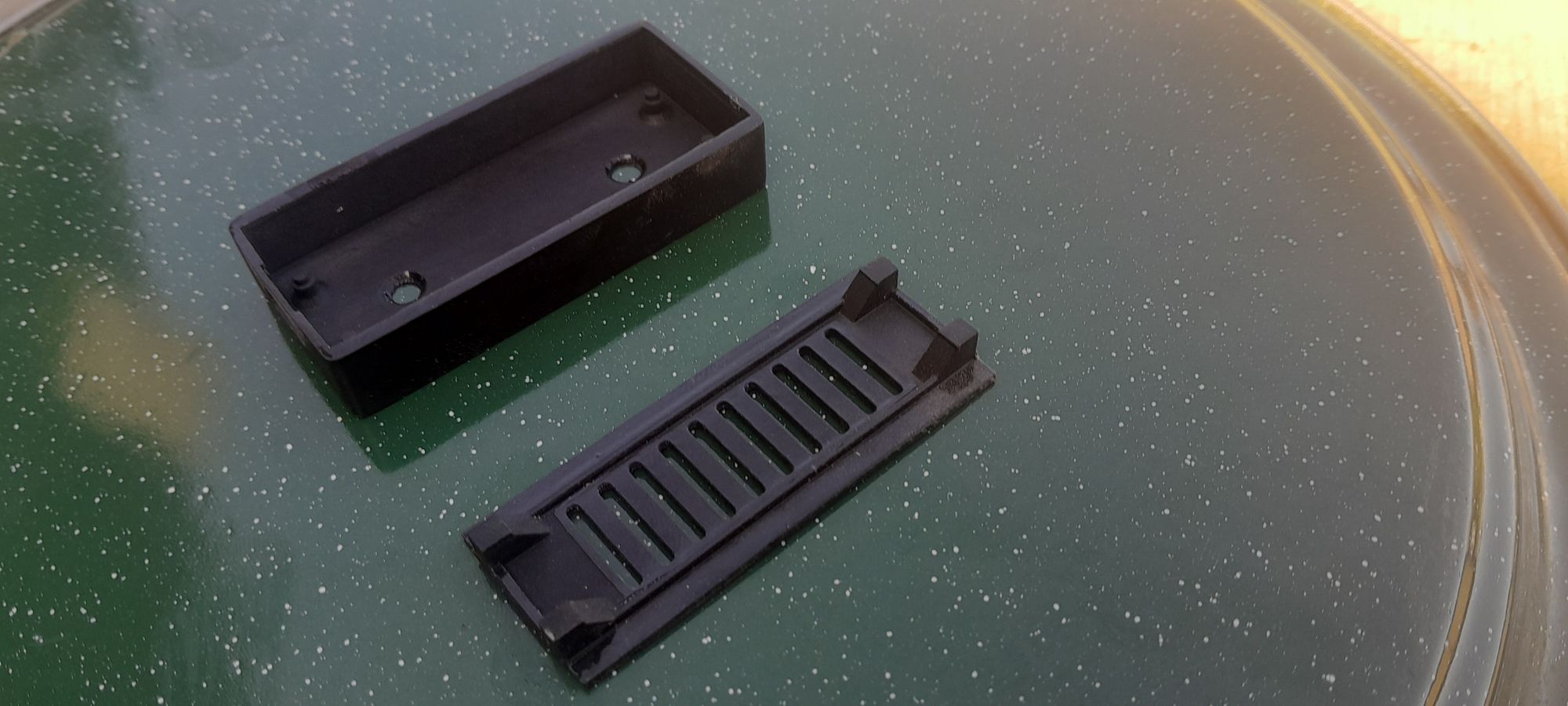

Silicone Replica Injection Molding is a game-changer for small runs. Though less dimensionally accurate and more expensive per part at low volumes, it’s an affordable option that fills the gap between high-volume 3D printing and low-end injection molding.

For years, I struggled to find a solution for small production runs. This process was the missing link, bridging the gap where 3D printing ends and traditional injection molding begins.

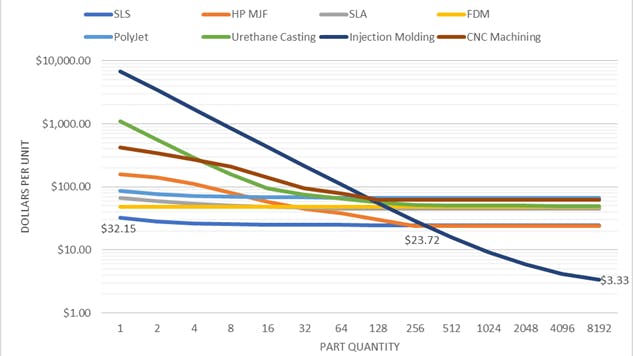

Cost per unit VS part quantity

Source: here page 181 "Generalised cost curve of 3D printing versus injection-moulding"

example cost part (a drone leg)

Between 128* and 255* part mark is when low volume silicone replicas injection molding make sense for low volume prototyping.

Source: xometry

* note numbers are super ruff. take with a grain of salt

Learning Lessons & Future Improvements

- Takeaways: This journey was way harder than it should have been, with many unknowns and challenges. But in the end, I succeeded.

- Cost Comparison: I ended up paying only $120 USD, a staggering 66X cheaper than traditional injection molding.

Call to Action

You can do this too! Don’t let high costs deter you from exploring these methods for your personal projects. Whether you’re looking to design a custom part, improve an existing one, or test new ideas, affordable injection molding opens up possibilities previously reserved for large-scale manufacturers.

Where Do I Take It from Here?

Unanswered questions remain: How do I get funding for a production run? Can I sell on Amazon? Should I consider pre-orders? The journey continues, with plans for future improvements, testing, and scaling up.

Helpful Tips: What I Wish I Knew When I Started

- Documentation: Create a living document for all questions to ensure smooth transitions between reps and techs.

- Shipping Considerations: Be aware of hidden costs like shipping, import fees, and unexpected shrinkage in parts.

- Negotiation Insights: Use your knowledge of Alibaba’s commission structure to your advantage.

Financial Considerations

Keep your money in USD until your product arrives, and consider ranking payment methods by security and convenience. Remember, lower-cost injection molding opens doors to prototyping with production-like quality, making it easier to transition from development to production.

Conclusion

Affordable injection molding isn’t just about saving money—it’s about unlocking the potential for rapid prototyping and small-scale production. With the right approach, you can achieve what seems impossible, turning your ideas into reality without breaking the bank.

Thanks for reading

Author

by o̴̝̩͊̅͝ŕ̵͙̝ͅḁ̵͓͓͊̈́̊͘n̵̰̕ ̷̠̰̮̆́̓̇͜ĉ̴̭̙̩̱͑̐o̸̫͙̽l̴̰̹̬̥̔͐̄l̶̳̽͝͠i̶͎͍̮̋͛͌n̶̛̲͔͈͙͌̌͐s̴̠̈́̾

github.com/wisehackermonkey